Machining

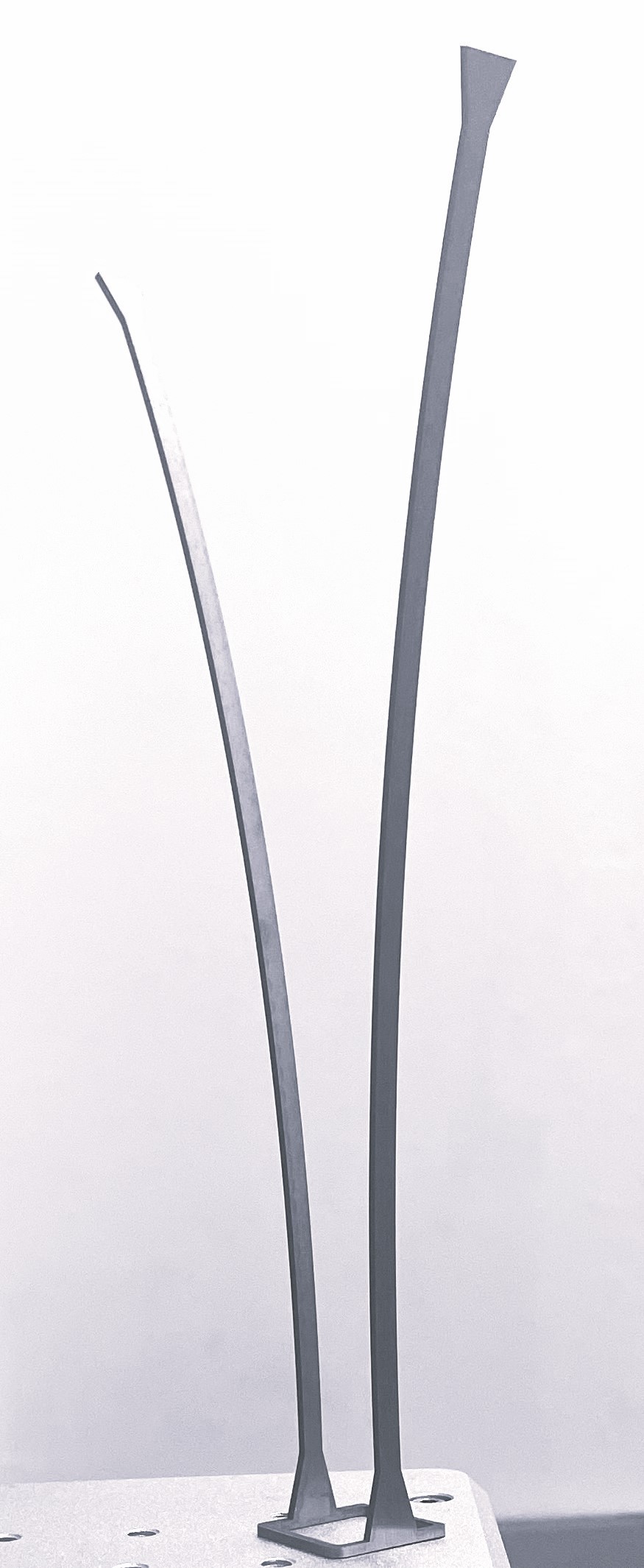

Product-Specific Wire-Cutting Services

- Metal Molds: Utilizing high-precision multi-cutting techniques, we ensure accuracy in tapered cuts and maintain precise cutting positions within the entire part.

- Plastic Molds: We provide high-precision cuts, including angular cuts, focusing on maintaining position accuracy throughout the entire piece.

- Oil Field Parts: Handling expensive materials with thick cuts, we take special care to prevent material deformation during the cutting process.

- Aerospace Materials: Specializing in nickel and titanium alloys, we manage deformation and discoloration, ensuring high-quality rough cuts. Titanium surfaces may turn purple during processing due to oxidation.

- 3D Printed Parts: Our services include cutting off 3D printed parts with simple yet precise cuts. We implement measures to prevent wire breakage and ensure parts do not fall and cause damage.

- Small Machine Parts: Efficiently arranging parts for unattended processing, we ensure they are ready for final cutting the next day.

- Precision Parts: We offer triple cutting for precisely arranged parts, enabling unattended processing and readiness for final cutting the next day.

Material-Specific Wire-Cutting Services

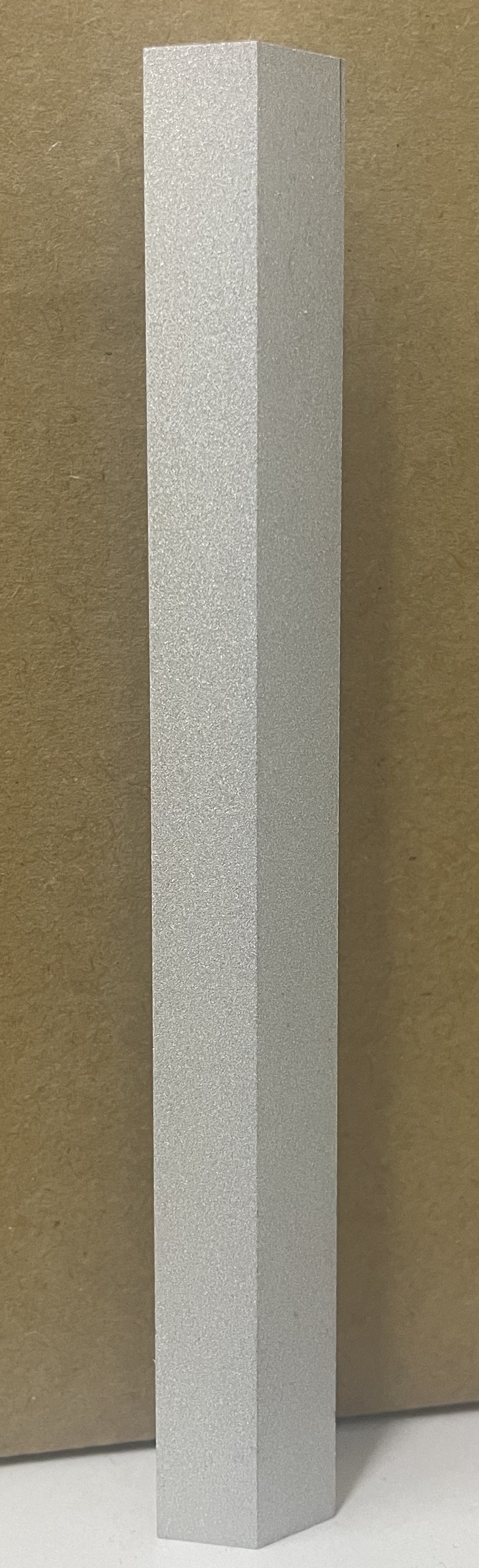

- Aluminum Cutting: Fast processing with challenges in achieving precision due to shape deformation. Adjusting discharge parameters ensures stability and accuracy.

- Copper Cutting: Slower processing prone to wire breakage from copper residue on the electrode wire. Extended pulse width is required for stable processing.

- Tungsten Steel Cutting: Slow processing requiring high current for effective cutting.

- Tungsten Copper Cutting: Combining properties of copper and tungsten steel, processing is slow and requires specific adjustments.

- Molybdenum Cutting: Extremely high melting point makes it challenging to process. Very slow processing speed necessitates precise discharge parameter adjustments.

- Titanium Alloy Cutting: Conductive properties lead to surface oxidation turning purple. Requires reduced discharge current to manage this.

- Magnesium Cutting: Highly flammable even at room temperature. Fire prevention measures are essential during cutting.

- Cast Iron Cutting: High carbon content makes processing difficult and slow, requiring specific discharge parameter adjustments.

- Pig Iron Cutting: Easy to cut but prone to material deformation.

- Stainless Steel Cutting: Easy to cut but internal stress can cause deformation. Processing must account for this impact.

- Steel Cutting: Easy and fast processing, providing high-quality results.

Height-Specific Wire-Cutting Services

- 0-20mm: Thin materials are prone to deformation and require smaller discharge conditions.

- 30-70mm: Ideal height for wire cutting, offering optimal processing speed and precision.

- 90-150mm: Increased thickness affects speed, which can be managed with adjusted discharge conditions.

- 200-300mm: High thickness significantly affects speed, making processing more challenging.

- 300-400mm: Very high thickness results in extremely slow processing speed, requiring specialized handling.

💡

Contact Us for Precision Wire-Cutting Services

Experience the precision and expertise of IS Machine Pte Ltd for all your wire-cutting needs. Contact us today to discuss your project requirements and receive a customized quote.

Experience the precision and expertise of IS Machine Pte Ltd for all your wire-cutting needs. Contact us today to discuss your project requirements and receive a customized quote.

📱WhatApp 📧Email ☎Phone

© 2024 V2.1 IS Machine PTE LTD. All rights reserved.