Breakthrough Highlights of MWE6 Pro-400 中文链接

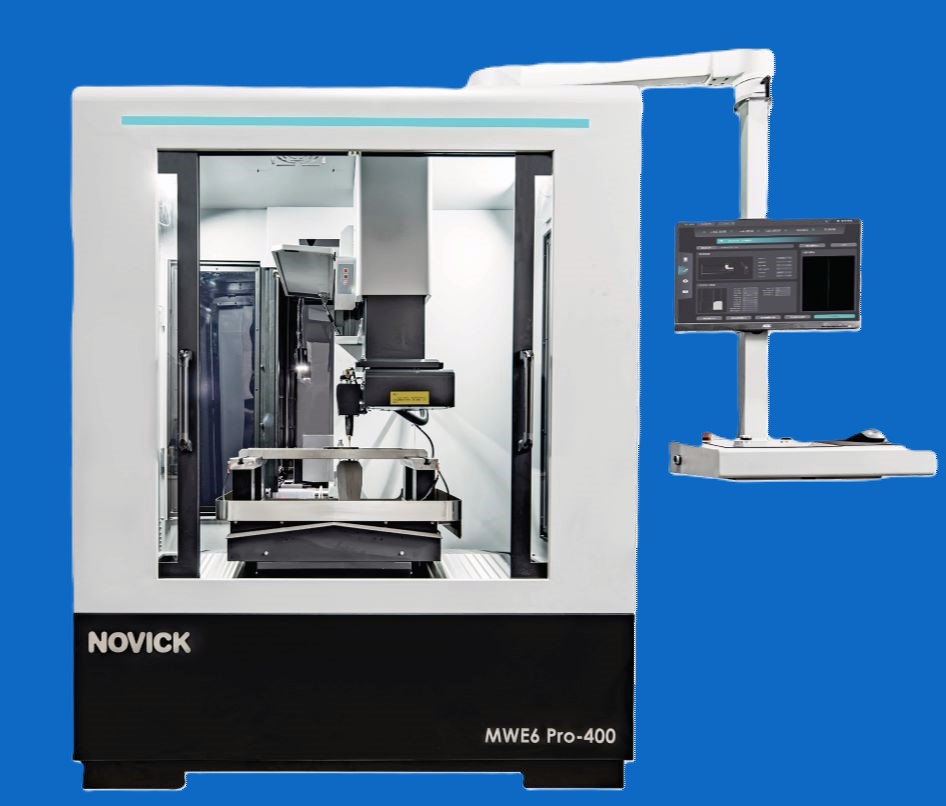

The MWE6 Pro-400 combines the advantages of medium-speed and brass wire cutting machines. Its automatic threading system simplifies the operation process and reduces labor costs. The multiple cutting function, combined with water-based coolant, ensures efficient, precise, and cost-effective processing, while further reducing electricity expenses.

Key Advantages

The MWE6 Pro-400 is equipped with an advanced automatic threading system. Say goodbye to manual threading and significantly improve your production efficiency with reduced manual intervention. This automatic threading feature marks a major breakthrough in medium-speed wire cutting technology, making your production process more seamless and hassle-free.

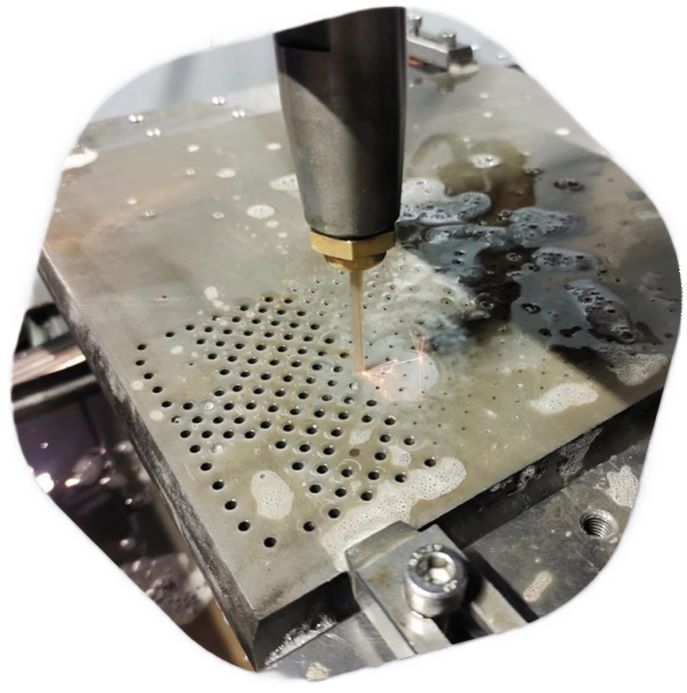

Utilizing molybdenum wire for reciprocating cutting, this machine balances the low operating costs of fast wire cutting with the high processing speeds of slow wire cutting, ensuring efficient processing while significantly reducing operational costs.

Achieve impeccable surface finish with the MWE6 Pro-400's high-precision cutting capabilities. The multiple cutting function ensures the accuracy and quality of your workpieces, meeting your stringent standards.

The use of water-based coolant is not only environmentally friendly and odor-free but also helps lower electricity costs. Compared to traditional oil-based coolants, maintenance is simpler, reducing long-term operational issues.

MWE6 Pro-400

Features:

- Enhanced Wire Feeding Mechanism:

Introduced an industry-leading automatic threading system, eliminating the traditional manual threading for medium-speed wire cutting.

- Tension Control:

Intelligent closed-loop constant tension system for real-time control, ensuring stable tension throughout the cutting process.

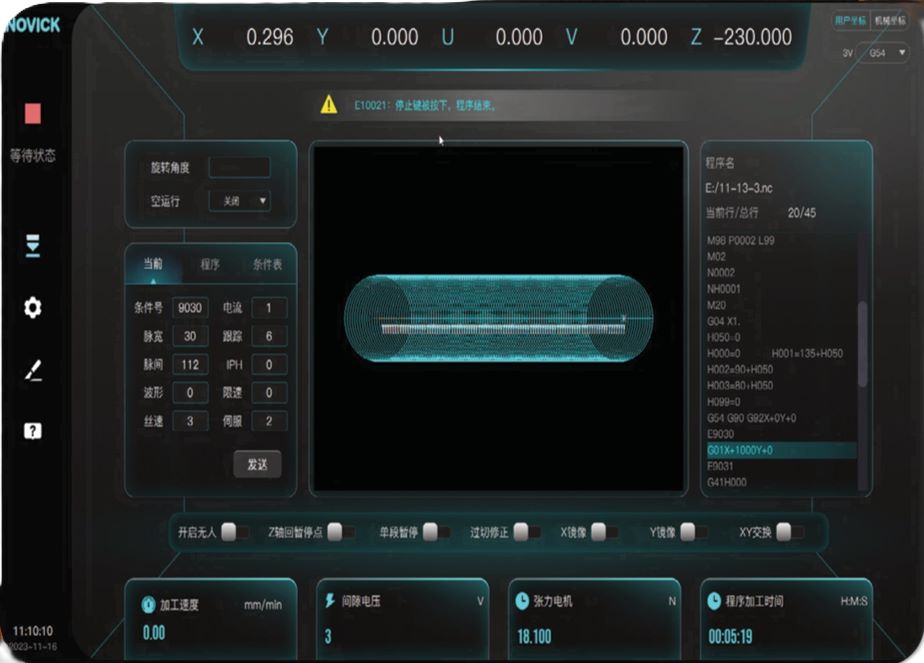

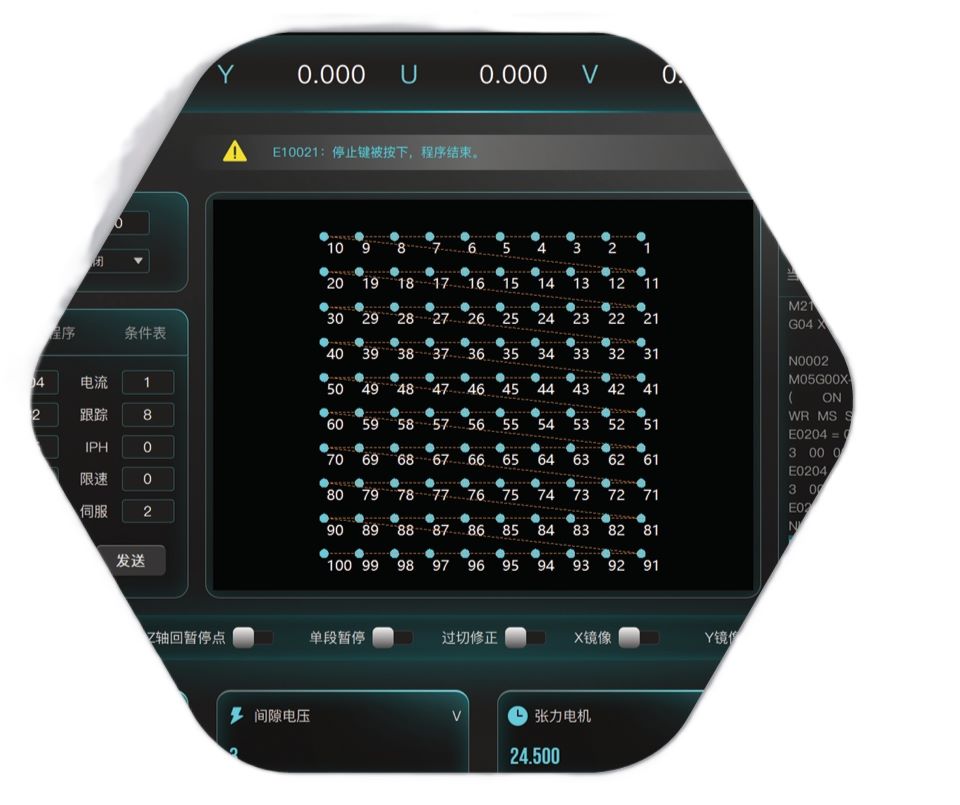

- Advanced Programming System:

Supports automatic programming for multiple cavities, taper, local taper, irregular shapes, and chip-free processing.

- High-Speed Pulse Power Supply:

Utilizes high-speed single-chip microcomputer to sample each discharge pulse for improved processing stability, speed, surface finish, and reduced wire wear.

- Environmental and Smart Design:

The sixth-generation machine offers clean, intelligent operations, suitable for automated production lines.

- Improved Filtering System:

Enhanced sedimentation trough around the machine cabinet for better cutting fluid filtration, resulting in better surface finish.

- Unattended Operation:

Supports automatic threading and chip collection, enabling night-time unattended operation for multiple cavity templates, reducing labor costs and increasing machine utilization.

This machine brings significant advancements in medium-speed wire cutting technology, offering features that enhance productivity, precision, and ease of use, making it a valuable tool for automated production environments.

Specifications:

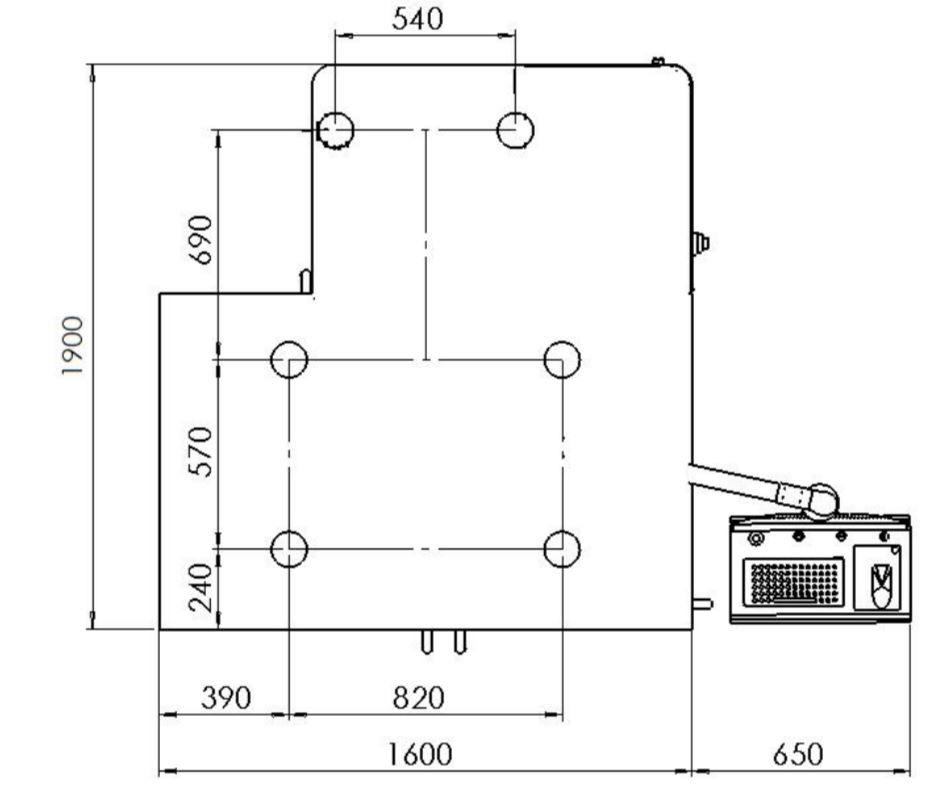

- Overall Dimensions (including electrical cabinet): 2250x1900x2200 mm

- Total Weight (including electrical cabinet): 2300 kg

- Height from Worktable to Ground: 990 mm

- Worktable Dimensions: 650x460 mm

- X/Y Axis Travel: 400x300 mm

- U/V Axis Travel: 70x70 mm

- Z Axis Travel: 250 mm

- Maximum Cutting Taper: ±5º/80mm (with guide)

- Maximum Cutting Thickness: 300 mm

- Maximum Workpiece Weight: 500 kg

- Maximum Workpiece Dimensions: 960x550x300 mm

- Wire Feeding Motor: AC servo motor control

- Wire Tension Control: Constant tension

- Minimum Threading Wire Diameter: Φ1.0 mm

- Threading Success Rate for Holes with Diameter ≥ Φ1.0 mm: 98%

- Standard Power Supply: 3x415V 50/60Hz 2kVA

- Permissible Voltage Fluctuation: 415V±10% 50±1Hz

- Full Load Current: 3 A

- Cooling System: Air conditioning

- Maximum Processing Current: 20 A

- Maximum Processing Speed: 300 mm²/min

- Best Surface Roughness (one cut, two trims): Ra≤0.8 μm

Technical Background

- Fast Wire Cutting Machines:

Utilize molybdenum wire for reciprocating cutting with oil-based coolant, single-pass cutting, and manual threading. While low in cost, they offer lower efficiency and quality.

- Traditional Medium Wire Cutting Machines:

Utilize molybdenum wire for reciprocating cutting with water-based coolant, multiple cutting, and manual threading. They are cost-effective but challenging to achieve automatic threading.

- Brass Wire Cutting Machines:

Utilize brass wire for automatic threading with pure water cooling, multiple cutting, offering high precision and surface finish at a high processing cost and expensive machine price.

Multimedia Resources

Automatic Threading Videos

📱WhatApp 📧Email ☎Phone

© 2024 V2.1 IS Machine PTE LTD. All rights reserved.